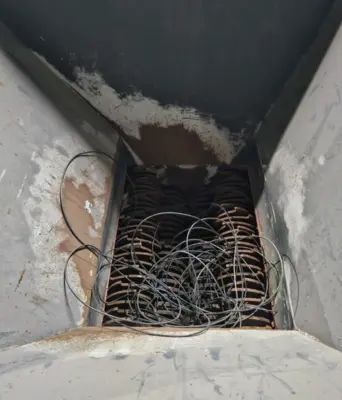

Heavy-duty industrial shredding machine designed for reliable volume reduction of bulky or difficult materials. It uses four counter-rotating shafts equipped with cutting and clearing discs to grab, shear, and tear materials in a controlled, high-torque, low-speed shredding action

🛠 Configuration

Shredder type: Four-shaft / quad-shaft low-speed shredder (2 cutting shafts + 2 clearing/broaching shafts)

Operation: Low shaft speed (~25 rpm) for high torque and quieter operation

Automatic features: Overload protection and automatic reverse on jam/loading

📊 Drive & Motor

Electric motors: Dual motors — typical configurations include 2 × 15 kW up to 2 × 30 kW (~20 – 40 HP each)

Voltage: 460 V / 3 phase / 60 Hz (common in North America)

Gear drive: Planetary gearboxes for high torque

📏 Mechanical Dimensions

Hopper opening (approx): ~1500 mm wide (feed width) (varies by build)

Cutting chamber working width: ~990 mm (≈39 in)

Rotor (shaft) diameter: ~280 mm (~11 in)

Shaft speed: ~25 rpm (low-speed, high-torque)

Typical overall weight: ~3000 kg (≈6600 lbs)

📦 Cutting & Throughput

Cutting discs: Hardened cutting discs on each shaft (size and number can vary)

Screened output size: Determined by the screen under the shafts — common diameters 10 – 150 mm depending on screen choice

Throughput: Approx 600 – 1500 kg/h (varies widely by material type and screen)

⚙️ Features

Heavy-duty construction with reinforced frame and wear plates available

Changeable screens and optional quick-change screen systems

Flexible feed options (hopper, conveyor, forklift, tipping device)

Discharge via suction, conveyor, or screw conveyor

PLC controls often included for operation and automatic reversal

We use cookies to improve your experience. Privacy Policy.