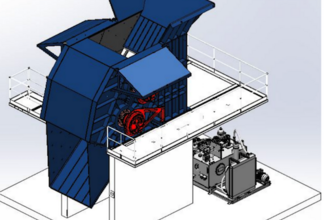

PSZB-2115 New ZB Group Pre-Shredder

Shredders

Increase the capacity of your existing shredding system, decrease risk of fuel tank ignition and reduce handling complexity. 40-60 MT/H capacity depending on material being processed.

PSZB-2115 is a heavy duty pre-shredder manufactured in S355JR (1.0045) high quality steel plates forming a robust solid. It is equipped with two heavy-duty rotors (equipped with toothed discs) that turn at different speed and in opposite directions. The top and bottom rotors toothed discs alternate to tear the material to be processed apart. Whenever the rotors torque reaches a preset value both rotors change turning sense to release the pre-shredder.

- Pre-shredder internal width: 2100 mm (83")

- Driven by low-speed high-torque hydraulic motors (2 per rotor)

- Electric or diesel power plants available

- Processing Capacity: 40 to 60 MT/H

- Weight: 62MT (approx. 137,000 lbs)

Toothed-Discs Rotors:

- Top Rotor (low speed) discs: 3

- Top Rotor (low speed) teeth per disc: 8

- Top Rotor (low speed) discs diameter (incl. teeth): 1500 mm = 59"

- Top Rotor (low speed) maximum speed: 2 rpm

- Top Rotor (low speed) and flipper driving power: 90 kW

- Top Rotor (low speed) maximum torque: 300.000 Nm

- Bottom Rotor (high speed) discs: 4

- Bottom Rotor (high speed) teeth per disc: 8

- Bottom Rotor (high speed) disc diameter (incl. teeth): 1500mm = 59"

- Bottom Rotor (high speed) maximum speed: 10 rpm

- Bottom Rotor (high speed) driving power: 355 kW

- Bottom Rotor (high speed) maximum torque: 300.000 Nm

Hydraulic Unit:

The pre-shredder includes its own hydraulic unit (with all needed components for its correct operation and with all required protection devices) equipped with two motor-pumps (355kW and 90 Kw) to operate all the hydraulic traction units (low-speed high-torque hydraulic motor, etc.) and the hydraulic cylinders. The hydraulic piping from hydraulic units to all the hydraulic devices is made by flexible hoses and rigid pipes.

Controls:

PLC controls are integrated in the pre-shredder and offer remote monitoring & service.

Emergency Stops: Pre-Shredder is equipped with emergency stops and safety devices in order to work in a safe working environment.